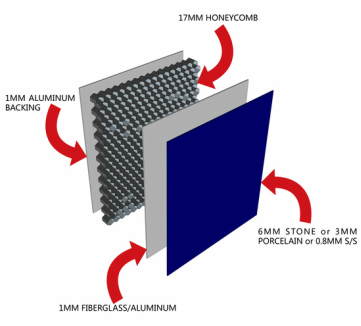

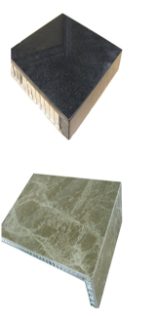

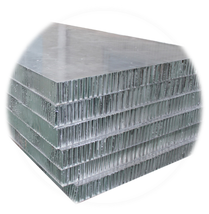

HyCOMB Panels (Non Combustible Aluminium Honeycomb Panels)- An Innovative facade cladding system.

Advantages of HyComb

|

• HyComb Aluminium Honeycomb panels are non combustible AS1530 compliant.

• lightweight: weight saving of up to 90% compared to when using solid dimension stone slabs • 5 to 10 times faster to install than solid heavy dimensional stone, saving construction time and reducing labour costs. • bigger panels can be adopted, meaning less joints • large format sizes of up to 3000mm X 1500mm in stone and even larger on pvdf coated aluminium. • huge labour savings that come from the engineered fixing system that allows for a very efficient installation process. • easier & faster installation meaning less labour cost & safer in OH&S • structurally proven to be stronger than dimension stone • other veneer fascia materials such as porcelain and PVDF coated stainless steel panels • less environmental impact due to using lesser quantity of natural stone used • more cost effective meaning creating more attractive design solutions • overall better visual benefits and performance characteristics than stone façade • Stone honeycomb panel can use in exterior cladding, interior fitting out and furniture. |

Additional Info |

• our factory produces aluminium stone honeycomb panels which are CSIRO, ASTM, BS and PSB test approved. • our current production capacity of HyCOMB non combustible aluminium honeycomb panels is 3 million square metres per year • our panels are popular in building applications in many overseas markets such as Australia, USA, Spain, Russia, Singapore, Korea, Hong Kong, Macau and Japan. • ISO 9001:2008 Quality Control/Assurance Adopted • freight forwarding • end to end logistics • supply and install • Assistance with design and construct |

Safety and Certifications

• ASTM and PSB test approved.

• AS1530 compliant

• ISO 9001:2008 Quality Management Systems

• Certificate of Conformity (PSB Singapore) Standards BS 476-4:1970; BS 476-6:1989/A1:2009; BS476-7:1997

• Fire, density, flex, core strength, compression strength standards etc., (Intertek USA) ASTM E84 (2012c); ASTM E84(2010); ASTM E84 (2013a); ASTM C271/C271m (2011); ASTM C273/C273m (2011); ASTM C297/C297m (R2010); ASTM C365/C365m (2011a); ASTM C393/C393m (2011 E1)

• Miami-Dade County, Floride High Velocity Hurricane Zone (HVHZ), Notice of Acceptance certification.

• AS1530 compliant

• ISO 9001:2008 Quality Management Systems

• Certificate of Conformity (PSB Singapore) Standards BS 476-4:1970; BS 476-6:1989/A1:2009; BS476-7:1997

• Fire, density, flex, core strength, compression strength standards etc., (Intertek USA) ASTM E84 (2012c); ASTM E84(2010); ASTM E84 (2013a); ASTM C271/C271m (2011); ASTM C273/C273m (2011); ASTM C297/C297m (R2010); ASTM C365/C365m (2011a); ASTM C393/C393m (2011 E1)

• Miami-Dade County, Floride High Velocity Hurricane Zone (HVHZ), Notice of Acceptance certification.

In-House Laboratory

In addition to the safety certification, our factory has their own in-house laboratory conducting multiple tests on HyCOMB panels. In-house testing includes:

• Flatwise compressive testing

• Flatwise tensile strength

• Shear strength

• High - low temperature tests

• Pull out test for clips

• Node strength test

• Accelerated aging test

• Acid and alkaline test/salt spray test

Random samples are taken out from our production line as a specimen for testing, to ensure the stability of panel performance. Test results are recorded into a database so each specific batch of production.

• Flatwise compressive testing

• Flatwise tensile strength

• Shear strength

• High - low temperature tests

• Pull out test for clips

• Node strength test

• Accelerated aging test

• Acid and alkaline test/salt spray test

Random samples are taken out from our production line as a specimen for testing, to ensure the stability of panel performance. Test results are recorded into a database so each specific batch of production.